A I-Galvanime Couily Coyil linephepha eliqengqelwe ngentsimbi edityaniswe ne-zinc. Lo mmandla we-zinc ukhusela intsimbi kwi-rump kunye nomonakalo, owenza ukuba amalahle aqine kwaye aqine. Inkampani yethu ibonelela ngeemveliso zensimbi ePhakamileyo yensimbi esetyenziswa ngokubanzi ziifektri kunye nabakhi bezakhiwo, ukuvelisa, kunye neenxalenye zemoto. Ngowama-2022, malunga nezigidi ezili-140 zeetoni ze-metrickin ze-coil zensimbi ye-Gallic eveliswe kwihlabathi liphela, kunye nemveliso ekhokelayo yaseTshayina. Iimveliso zethu zenzelwe ukuhlangabezana nemfuno ekhulayo yeCoils yensimbi ethembekileyo kumashishini ahlukeneyo.

Iqhosha lezitshixo

I-Galvanime Couil Coyil iqhekeza i-zinc. I-zinc inceda ukuyeka umhlwa kwaye yenza intsimbi ihlala ixesha elide. Oku kwenza ukuba ibhinqa liqinile kwaye lilungile kwizinto ezininzi.

Kukho iintlobo ezahlukeneyo kunye namabakala aBakala oShiyine lwensimbi. Uhlobo ngalunye lusebenza kakuhle kwimisebenzi ethile. I-tick chinc coats ikhusela ngcono ngaphandle. Iingubo ezincinci zingcono ngaphakathi okanye zibukeka.

I-HOT-dip-dip, i-pre-thervaning, kunye ne-electrogalvanations zindlela zokongeza i-zinc. Ngandlela nganye inika ubungqibelo olwahlukileyo kwaye ujongeke. Inye isetyenziselwa iimfuno ezizodwa.

I-Galvanime Couil Clail isetyenziswa kakhulu ekwakhiweni, iimoto, kunye nooomatshini basekhaya. Inceda ukugcina imali kuba ifuna ukulungiswa ezimbalwa kunye nokhathalelo oluncinci.

Ukukhetha i-coil elungileyo kuthetha ukucinga malunga nobungqingqwa, i-zinc caides, ibanga, nokuba isetyenziswe phi. Oku kunceda uqiniseke ukuba isebenza kakuhle kwaye ihlala ixesha elide.

Isishwankathelo se-biel yentsimbi

Yintoni i-Galvanimed Clail

I-Galvanime Couil yeStile yiphepha lentsimbi. Iqengqele kwi-coyini. I-coil igqunywe ngomaleko we-zinc. I-zinc igcina intsimbi ikhuselekile kwi-rump kunye ne-corosion. Iifektri kunye nabakhi bafana ne-Galvanimed Coil. Yomelele kwaye ihlala ixesha elide. Isebenza kakuhle nakwimozulu enzima. Ubumbano lwe-zinc block blocks amanzi kunye nomoya. Oku kunceda ukuyeka i-rust ukuba isebenze. Xa i-coil ingaphandle, i-zinc ihlangana ioksijini kunye nokufuma. Yenza ifilimu emdaka ekhusela i-coil. Le filimu inceda ukuba i-coil imelana nomonakalo.

I-Galvanime Couil Clail ineepropathi ezininzi ezibalulekileyo:

Ipropathi |

Ixabiso eliqhelekileyo |

Ukubaluleka / iNzuzo |

Ukuxinana |

Malunga ne-7.85 G / CM⊃3; |

Ubungakanani bomgangatho oqhelekileyo ofanelekileyo kwizicelo zesakhiwo |

Ubunzima bomzimba |

30-350 G / M⊃2; (amacala omabini) |

Inika ukhuseleko lokukhuselwa eziguquguqukayo kwiindawo |

Ukubekwa komphezulu |

Rhabaxa (ra) 0.8-1.5 μm |

Ukonyusa ukunamathela okuthoba kunye nokuqina |

Ukuqhubela phambili kwe-thermal |

Ngaphandle kwe-Galvanie |

Ilungele izicelo zokusebenzela ubushushu |

Ukuqhutywa kombane |

Iphantsi kancinci kunentsimbi ecocekileyo |

Dibana neemfuno zokuphumelela kwimveliso |

Ukusebenza kolwando lwe-shirmal |

11.5 x 10º / ° C |

Iqinisekisa uzinzo oluhlala phantsi kotshintsho lobushushu |

Qaphela: Umaleko we-zinc unceda isithuthi sixhathise iichemicals. Ihlala izinzile kwiindawo ezine-PH ukusuka kwi-6 ukuya kwi-12. I-Coil inokuthintela ubushushu ukuya kuma-200 ° C ixesha elide. Ingathatha ukuya kwi-300 ° C ixesha elifutshane.

Iinkcazo eziphambili

Abavelisi benza i-gavanimed coil yentsimbi kubungakanani obuninzi. Benza nemilinganiselo eyahlukileyo. Ezona zinto zixhaphakileyo zinobubanzi, ububanzi, i-coin ubunzima, kunye nobubanzi bangaphakathi. Oku kunceda abathengi bakhetha eyona nto ibalulekileyo kwiimfuno zabo.

Iparamitha yokucaciswa |

Uluhlu oluqhelekileyo / ixabiso |

Ubukhulu |

I-0,12 mm ukuya kwi-0.8 mm (ethile ukuya kwi-4.0 mm okanye i-6.0 mm) |

Ububanzi |

I-600 mm ukuya kwi-1500 mm (eminye imithombo engama-600 mm ukuya kwi-1250 mm) |

I-Coin ubunzima bomzimba |

I-3 ukuya kwi-8 yeetoni zeMetric (umgangatho), ukuya kuthi ga kwi-25 Metric Tons ngesicelo |

I-Coil Inner |

I-508 mm okanye i-610 mm |

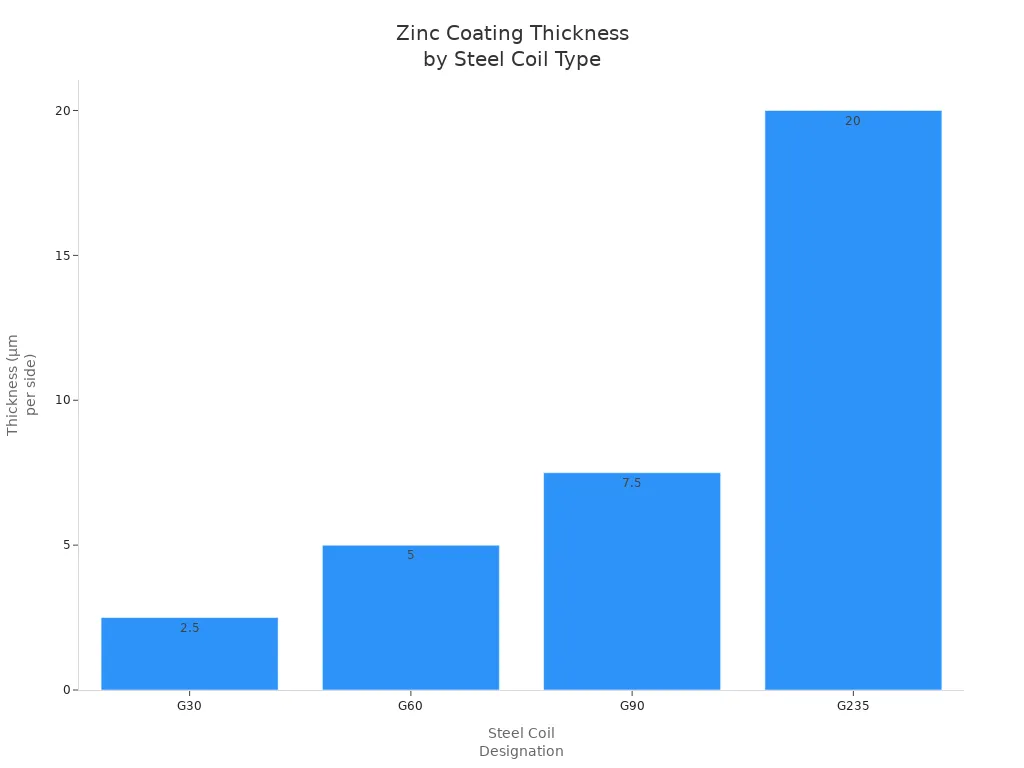

Ubungqingqwa bobuqili beZinc kubaluleke kakhulu. Ichaphazela indlela i-coyini ilwa ngayo rust. Ikwatshintsha kwaye i-coil ihlale ixesha elingakanani? Iikhoyili ezahlukeneyo zineentsimbi ezahlukeneyo zokuhamba kunye nobubanzi. Itheyibhile engezantsi ibonisa iintlobo eziqhelekileyo kunye neempawu zazo:

Indawo |

I-zinc diating ubunzima (oz / ft⊃2;) |

Ubungakanani obufanelekileyo (μm kwicala ngalinye) |

Ukuchasana okuqhelekileyo |

Izicelo eziqhelekileyo |

G30 |

I-0.30 iyonke (0.15 ecaleni) |

~ 2.5 |

Ukhuseleko lokukhanya |

I-Indoor ye-Indoor, izixhobo |

G60 |

I-0.60 iyonke (0.30 kwicala) |

~ 5 |

UKUKHUSELEKO NGOKUGQIBELA |

I-HVAC, ukukhanya kwangaphandle |

G90 |

I-0.90 iyonke (0.45 kwicala) |

~ 7.5 |

Ukhuseleko oluphezulu |

Uphahla, uhleli, ezolimo |

G235 |

2.35 Iyonke (1.175 kwicala ngalinye) |

~ 20 |

Ukhuseleko oluphezulu |

I-Marine, izigadi, iindawo eziphezulu zokuzonwabisa |

Indlela i-Zinc ifakwe kwi-wiling tshintsha ubukhulu bayo. I-HOT-dip-dip ye-dabvaning yenza iingubo ezinqabileyo. Ezi zihlala ziphakathi kwe-45 ne-100 imiqobo. I-Electro-Galvaning yenza iingubo ezincinci. Ezi zivela kwi-2,5 ukuya kwi-255Merter ezingama-25. Iingubo ezinzima zikhusela ngcono kodwa zixabisa ngaphezulu. Iingubo ezincinci zijongeka zilungile kwaye zisetyenziswa ngaphakathi okanye kumhlobiso.

I-GAIVAND COIL COIL kufuneka ilandele imigangatho yehlabathi. Le mithetho iqinisekisa ukuba i-coil ikhuselekile kwaye yomelele. Eminye imigangatho ebalulekileyo yile:

Umgangatho |

Umda / isicelo |

Amanqaku aphambili enkcazo |

I-ASTM A653 / A653m |

Iphepha le-STEEL, i-zinc-icediwe (i-Galvamid) okanye i-zinc-iron-iron |

Ukudibana komzimba, ukunamathezeka, umgangatho womphezulu, ubuncinci bokuthintela, ukugqiba, ukubonakala, ukubambelela |

I-ASTM A924 / A924m |

Iimfuno ngokubanzi zephepha le-SEE, i-metallic-idityaniswe yinkqubo eshushu yedip |

Iimfuneko ezihlekisayo ngokubanzi kubandakanya ubukhulu, amanembethe, kunye nomgangatho womhlaba |

I-ASTM A123 / i-123m |

I-HOT-dip-dip ye-dipvanings eshushu kwi-iron kunye neemveliso zensimbi |

Ubuncinci bokuthintela ubuncinci, ukugqiba okuqhubekayo okuqhubekayo, akukho ndawongafuziswanga, ukubambelela ngokuqinileyo kubomi benkonzo |

ISO 3575 |

Iphepha le-bip le-finc-dip-comited ye-winc-ye-carbon yensimbi ye-Carbon Stee yeSteel yeSteel kunye neempawu zokuzoba |

Ubungqingqwa bokuthinta, imbonakalo, ukuxhathisa i-Porrosion |

ISO 1461 |

I-Dipvanings eshushu ye-galvanings kwi-Iron kunye namanqaku entsimbi-iinkcazo kunye neendlela zovavanyo |

Ubungqingqwa bokuthinta, imbonakalo, ukuxhathisa i-Porrosion |

I-ASTM kunye neMigangatho ye-ISO ibeka imithetho yokuthoba ubunzima kunye nobungqingqwa.

Iimvavanyo zijonga ukuba zinamathela njani i-zinc intsimbi kunye nendlela yokudlala ngayo.

Ukuchasana nokunyanzelwa kuvavanywa ngokutshiza kunye nezinye iindlela.

Iindidi kunye namaBakala

I-Galvanime Couil Coil ingena ngeendlela ezahlukeneyo namabanga. Uhlobo ngalunye lunezinto ezikhethekileyo kwimisebenzi ethile.

I-Hot-Dip-Dip eHip ye-Dieelid Coyils: Ezi ziko zenziwa ngentsimbi yentsimbi kwi-zinc. Oku kwenza ukuba i-faker enkulu, inzima inqabile. Abakhi basebenzisa i-DIP-DIP eshushu ze-dip izinto zangaphandle ezinjengophahla kunye nocingo.

I-Electro-I-Electro-Galvanimed Selel: Ezi ziko zifumana i-zinc usebenzisa umbane kwisisombululo. Umaleko uthambile kwaye uncumile. Iifektri zisebenzisa ezi ziko lezixhobo zemoto kunye nezixhobo ezifuna ukujonga okuhle.

Amabanga aBanga a- 'g ' kunye nenani. Inani libonisa ukuba ingakanani i-zinc ingakanani i-zinc. Amanani amakhulu athetha ngakumbi i-zinc kunye nokukhusela okungcono. G60, G90, kunye ne-G275 ngamabanga aqhelekileyo.

Uhlobo lwebanga |

Inkcazo |

Izicelo eziqhelekileyo |

Ibakala lezorhwebo |

Isabelo esikhulu sentengiso; Ukusetyenziswa ngokuBanzi |

Uphahla, hlala |

Ukuzoba umgangatho |

Isetyenziswe kwimveliso ebolekileyo yentsimbi |

I-Automotive, izixhobo |

Amandla aphezulu aphantsi |

Amandla aphezulu kunye nokuqina |

Iibhulorho, izakhiwo, iinqanawa |

Ibakala lezakhiwo |

Isetyenziselwe ukwakhiwa kweebhulorho kunye nezakhiwo |

Izikhokelo zolwakhiwo |

Abanye |

Amabakala akhethekileyo anepropathi ethile |

Izicelo ezahlukeneyo ezizodwa |

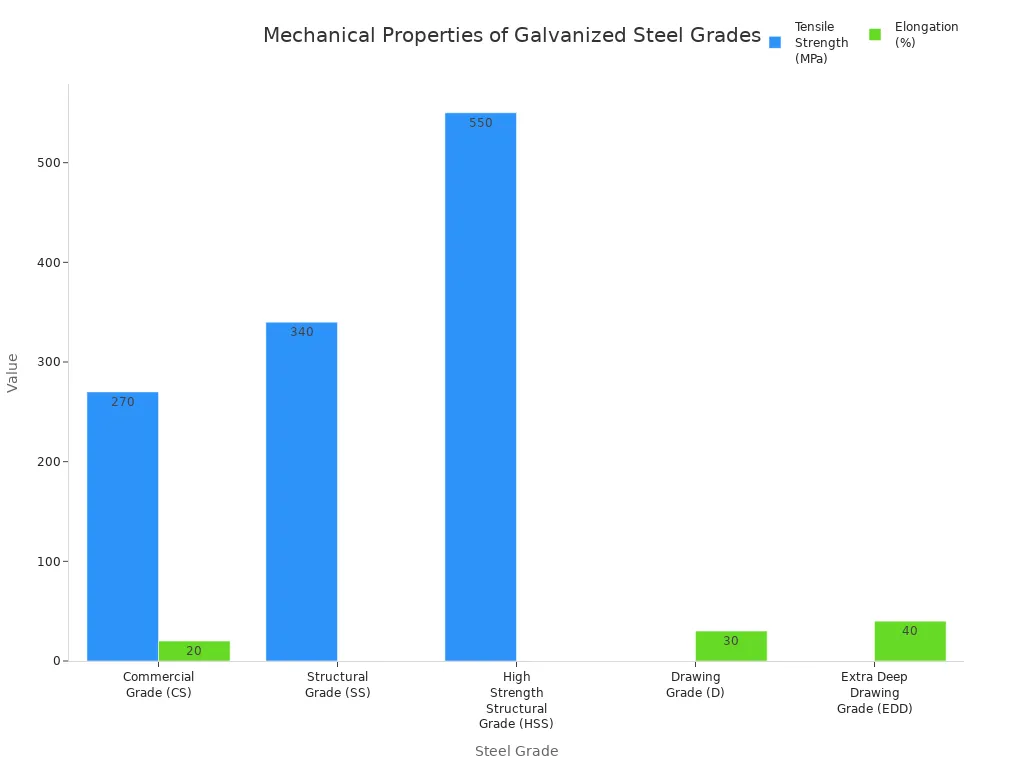

I-ProPries yoomatshini itshintsha iBanga ngalinye. Itheyibhile engezantsi ibonisa indlela amandla kunye nokuguquguquka okwahlukileyo:

Ibanga |

Amandla e-thensle (MPA) |

Isivuno (MPA) |

I-Elongition (%) |

I-CoreEl |

Isicelo esiqhelekileyo / ukuqhubekeka |

Ibakala lezorhwebo (CS) |

270 - 410 |

N / A |

≥ 20 |

Isiseko esisiseko sokuphelisa, amandla aqhelekileyo |

Ukugoba ngokulula kunye nokusika (akukho sitampu esinzulu) |

Ibakala lolwakhiwo (ss) |

340 - 550 |

≥ 230 |

Ngokulinganiselweyo |

Amandla aphezulu kunye nobuqhetseba |

Ukuthwala umthwalo, ukunxibelelana kwe-well |

Ukuzoba iBakala (D) |

Ngokulinganiselweyo |

N / A |

≥ 30 |

I-ducity ephezulu kunye ne-elongiza |

I-Meding Stample |

Ibakala elingaphezulu lokuzonda (i-EDD) |

Isezantsi |

N / A |

40 |

Ukungasebenzi okukhulu, ukumelana nokuncipha |

Ukunyibilika okuntsonkothileyo kunye neembumbulu ezichanekileyo |

Amandla aphezulu eMandla (HSS) |

I-550 - 980 |

Umyili we-Wield 0.85 |

Ngokulinganiselweyo |

Inqanaba eliphakamileyo elinamandla-ukuya kwi-Rurious, ukufunxa kwamandla aphezulu |

Ukulungiswa okukhethekileyo (i-laser cute, i-hydraulic ye-hydraulic) |

I-Galvanime Couil yentsimbi inezinto ezahlukeneyo zomphezulu:

I-Spangled rhoqo: Ungabona amakristali eZinc. Isetyenziselwa ukwakhiwa.

I-Spangle encitshisiweyo: Iikristali ezincinci zenza umphezulu oshukumayo. Isetyenziswe kwiimoto kunye nezinto zombane.

I-Zero Spangle: Akukho zikristali zibonwa. Umphezulu uyakhanyisa kwaye ugudile. Isetyenziswe ekutyeni kunye namashishini emichiza.

Iingubo ezikhethekileyo: Ezinye iikhoyili zineminwe eyongezelelweyo yeminwe, iibhakteria, okanye ubushushu.

Icebiso: Khetha uhlobo olusekunene kunye nenqanaba lomsebenzi wakho. Iingubo ezinzima kunye namabakala aphezulu zilungele ngaphandle okanye kwiindawo ezinzima. Iingubo ezincinci kunye ne-roughts ezigudileyo zilungile ngaphakathi okanye kumhlobiso.

Iindlela zemveliso

I-HOT-dip-dip ye-dipvaning

I-datvaning eshushu ye-dip yeyona ndlela ithandwayo yokukhusela iikhoyili zensimbi. Okokuqala, abasebenzi bacoce intsimbi. Bathatha kwaye bangathathi cala kumphezulu. Emva koko, bathembisa i-coil kwi-zinc. Oku kwenza ukuba i-zinc ye-zinc-yentsimbi yentsimbi. Emva kokuntywila, i-coil ipholile. Abasebenzi bayiphathe ngokudlulisa kunye neoyile. La manyathelo ancedayo i-hainting hands kwaye ujongeke ngcono. Abahloli bajonga ubukhulu kunye nokuba ijongeka njani. Emva koko, i-coil iqhubekile. Umaleko we-zinc unzima, ngokufuthi ezingama-45 ukuya kwi-85 micrometers. Lo mdlalo we-ASTM ulawula njenge-A123 kunye ne-A653. Inkqubo inceda ukulwa kwentsimbi kunye nokukrwela. Kuhle kwizakhiwo ezingaphandle kunye nemisebenzi enzima.

Inkqubo yokuhamba:

Lungiselela kwaye ucoce umxholo

I-Pick kwaye isuse igrisi

Hlamba kwaye ungathathi cala

Yongeza ukuphindezela

Dip kwi-winc inyibilikisi

Kupholile kwaye uphathe i-coil

Tywina kwaye unciphise i-coil

Vavanya umgangatho

Sika kwaye uqengqele kwiikoreyini

Ukupakisha kwaye uthumele imveliso

I-pre-vevaning

I-Pre-Prevaning yenzeka kwi-teel mill ngaphambi kokubunjwa. Abasebenzi bacoca iphepha lentsimbi kuqala. Emva koko, bayiqhubela i-zinc inyibilikisi emgceni. Oku kwenza ukuba kugudise kwaye kwanesifo se-zinc. Ukudibana kuhlala kuyi-20 ukuya kwi-30 micrometers enkulu. Ukugqitywa kukhanya kwaye kulula ukubumba. Iindleko zentsimbi zangaphambi kwexesha zixabisa ngaphantsi kwaye zisebenza kakuhle kwimisebenzi emikhulu. Kodwa, bakwa imiphetho kunye ne-welds inokubonisa intsimbi engenanto. Oku kuthetha ukhuseleko oluncinci. I-PAR-PROVNAning ilungele izinto zangaphakathi okanye amalungu afuna ukubonakala emnandi.

Inqaku |

I-HOT-dip-dip ye-dipvaning |

I-pre-vevaning |

Ubukhulu becala |

45-85μm |

20-30 μm |

Ukugubungela |

Izele, kubandakanya imiphetho |

Hayi kwimiphetho yokusika |

Gqiba |

Umahluko |

Iyunifomu, iqaqambile |

Sebenzisa kakhulu |

Ngaphandle, unzima |

Indawo yokuhlala, ebonakalayo |

I-electrogalvaning

I-electrogalvaning isebenzisa umbane ukugubungela intsimbi nge-zinc. Abasebenzi bacoce intsimbi kuqala. Emva koko, bayibeka kwisisombululo esikhethekileyo. I-zinc ion inamathele kwintsimbi kwaye yenze into ecekeceke, nokubamba. Ukudibana kuhlala kuyi-5 ukuya kwi-25 micrometers enkulu. Intsimbi ye-electrogalvanited igudile kwaye icwebe. Igoba ngokulula kwaye ixhathise iindawo ezimanzi. Kulula ukupeyinta. Abantu bayisebenzisa kwiinxalenye zemoto, izixhobo zombane kunye ne-elektroniki. Inkqubo ilandela imigaqo ye-A879. Kulungile kwiimveliso ezifuna umphezulu ococekileyo kunye nokukhusela.

Qaphela: Intsimbi ye-electrogalvanited isebenza kakuhle ngaphakathi nangaphantsi kwepende. Imisa i-runst kulungile kodwa ayikhuselekanga ekunxibeleleni ngeendlela ezishushu.

I-Galvaneal

I-Gavaneling mixedes i-galvaning ngemfumba. Emva kokubekwa kwe-DIP eshushu, abasebenzi bashushu intsimbi ephezulu kakhulu. Oku kwenza ukuba i-hinc-iron ye-wincy aler. Umaleko unceda nge-welding kunye nokupeyinta. Intsimbi ye-Galvanewed ilula ukuyila kunye nobume. Isetyenziswe ezimotweni, izakhiwo, kunye nezinto zombane. I-ASTM A653 inika imithetho ye-cell yentsimbi ye-Galvanenead. Oku kugcina umgangatho kunye nokusebenza okungagungqiyo.

Iimpawu kunye neziBonelelo

Ukunganyangeki

Insimbi ye-Galvanited ayigutyubani ngokulula ngenxa ye-zinc yayo. Umaleko we-zinc ukhusela intsimbi phantsi. Xa amanzi okanye umoya uchukumisa i-coil, i-zinc iphendulile kuqala. Oku kwenza ukuba ikhaka elinqabileyo ioksijini namanzi ekufikeleleni kwintsimbi. I-chinclaier ye-zinc ikwadala imimandla ekhethekileyo enje (Zno), i-hydrozinecite, kunye neSimokolleite. Ezi nkunkuma zenza ifilimu. Ifilimu inciphisa i-run kwaye igcina ikhuselekile intsimbi. Nokuba i-coil ikhutshiwe okanye inqunyulwe, i-zinc isayikhusela. I-zinc itshintsha indlela yokutshintsha kwentsimbi. I-SINCHER ZING ZINCE ZIKAKHUSELEKO. Zihlala ixesha elide kwiindawo ezinzima.

I-winc ihlanya le-zinc inxiba ngaphambi kwentsimbi.

Ukukhusela iifilimu zebhloko yeoksijini namanzi kwintsimbi.

Izilungisi ezihlanjisiweyo ngokwayo ekukhubekeni okanye zisike.

I-winc-shries eziphambili inika ukhuseleko olongezelelekileyo kwiimeko ezinzima.

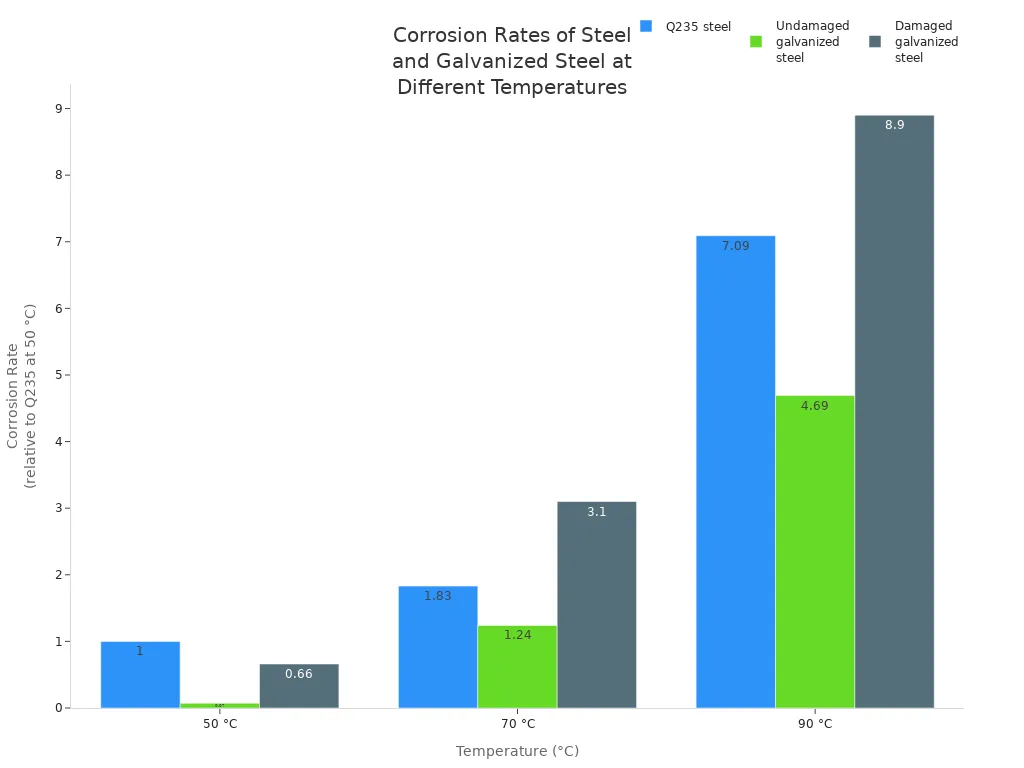

UVAVANYO UCINGISISIWEYO SE-GAELD BAREEL BAREAS STUNSIRN BROUSE INDLELA YOKUZIPHATHA NGOKUGQIBELA. Oku kuyinyani kwiindawo ezimanzi okanye ngaphandle.

I-Capten |

Inqanaba le-corrosion (i-50 ° C) |

Iimveliso eziphambili zemveliso |

Imveliso yeMveliso |

I-Q235 intsimbi |

1 |

Fe3o4 |

Khululeka |

Intsimbi ehleliweyo |

0.07 |

Zno |

I-munse |

Intsimbi elonakeleyo |

0.66 |

Fe3o4 + Zno |

I-munse |

Ukuqina kunye nokugcinwa

I-chinc caides inceda intsimbi ye-evanity ihlala ixesha elide. Isebenza ngaphandle kwemvula, ilanga, kunye nomoya. Abantu bayisebenzisa eluphahleni, ucingo kunye noomatshini. Intsimbi engapheliyo ihlala ixesha elide kakhulu kwiindawo ezinzima kakhulu. Kodwa intsimbi ye-inti ikhusela kakuhle kwaye iindleko zincinci. Ixesha elingaphezulu, umaleko we-zinc unokunxiba. Iitsheki rhoqo kunye nokulungiswa ngokulula ukugcina i-stal yomelele.

ICEBISO: Gcina intsimbi ye-gavanited kwiindawo ezomileyo. Bonga iikhoyisi ukuze uzikhusele. Jonga amanzi rhoqo. Ukuba ubona umonakalo, lungisa ngepeyinti ye-zinc okanye i-spray.

Iindlela zokugcina ezolondolozo:

Sebenzisa iikhemikhali okanye ioyile ukuyeka ukuxabana kunye nomonakalo.

Songa iiDills ngephepha okanye ngeplastiki xa ugcina okanye ukuthunyelwa.

Jonga amanzi kunye neekopi ezomileyo kwangoko ukuba zimanzi.

Lungisa ukupakisha ngokukhawuleza ukuyeka ukukratya.

Iivenkile ezigciniweyo kumagumbi alawulwa kwemozulu. Sukuzigcina ixesha elide.

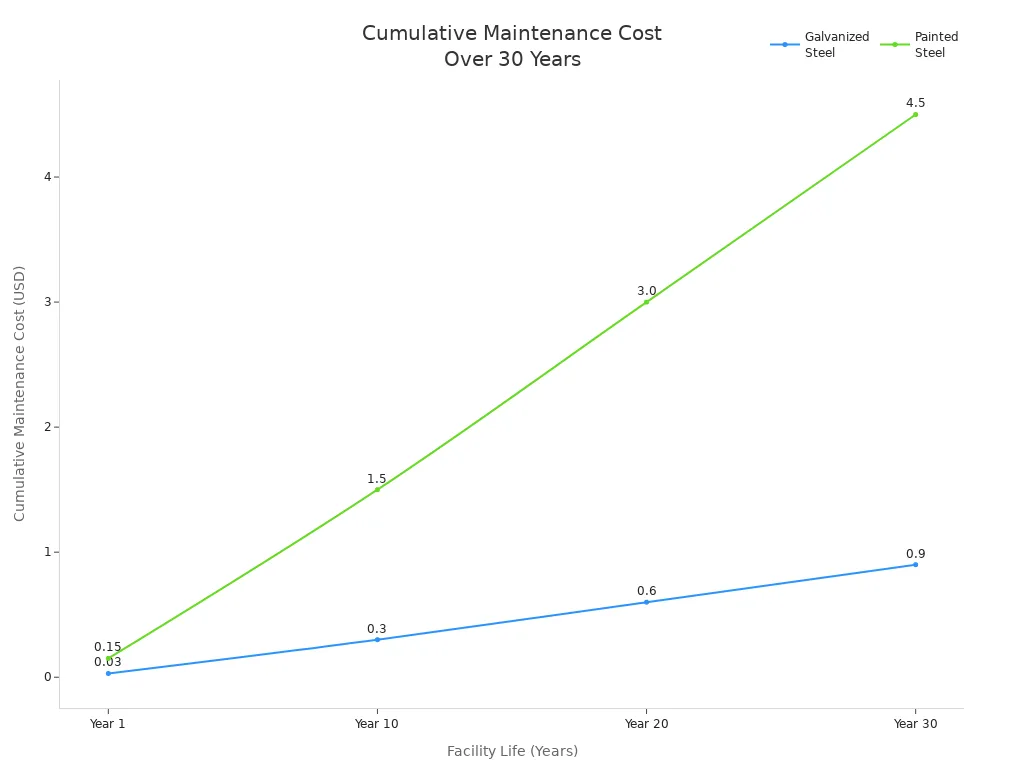

Ukusebenza kweendleko

Insimbi ye-Galvanited inika ixabiso elifanelekileyo lemali. Ixabisa ngaphezu kwentsimbi ecacileyo ekuqaleni. Kodwa iphantsi kunentsimbi engenasinyithi okanye i-upende. Ukudibana kwe-zinc kuthetha kuthetha ukulungiswa ezimbalwa kunye nokuguqulwa okuncinci. Oku kugcina imali ngokuhamba kwexesha.

Ixabiso lexabiso |

Intsimbi eshushu ye-dip-dip |

Inkqubo yentsimbi epeyintiweyo (ingubo ezimbini) |

Iindleko zokuqala |

Ukhuphiswano okanye ngaphantsi |

Ngamanye amaxesha ephezulu okanye efanayo |

Ulondolozo loNyaka |

$ 0.03 ngonyaka |

$ 0.15 ngonyaka |

Indawo yokuhlala |

Iminyaka engama-30 |

Iminyaka engama-30 |

Imfuneko |

Akukho |

Ukuphindaphinda |

Ixabiso lemijikelo yobomi |

Rhoqo iindleko zokuqala |

Ngaphezulu kakhulu ngenxa ye-upkeep |

Intsimbi ye-Galvanited inceda iindleko ekuhambeni kwexesha. Ifuna ukulungiswa ezimbalwa kunye nokutshintshwa. Ikwasindisa amandla kwizakhiwo. Oku kwenza ukuba kukhetho oluhle lokwakha nokwenza izinto.

Izicelo ze-Galvanimed Coil

Ukwakhiwa kunye nophahla

I-Galvanime Couil Clail ibaluleke kakhulu ekwakheni. Abakhi bayisebenzisa eluphahleni, iindonga, imiqadi, nemivalo. I-chinclaier igcina izakhiwo zikhuselekile kwi-rust kunye nemozulu embi. Oku kukwenza ukhetho olufanelekileyo lokusetyenziswa kwangaphandle. Yomelele kwaye ayiphumi ngokulula. Ihlala ixesha elide kwiindawo ezinobunzima. Abakhi abaninzi bakukhetha i-gavaninited coil yezakhiwo zensimbi, amagqwirha, kunye neephaneli zodonga. Malunga nesiqingatha sayo yonke i-coil yentsimbi esetyenziswayo ekwakheni. Izixeko ezininzi kunye neeprojekthi ezintsha zenza imfuneko yezixhobo zokukhula, ngakumbi e-Asiya-Pacific.

Ukwenza imveliso kunye nemoto

Iifektri zisebenzisa i-Galvanimed Coil yentsimbi kuba inzima kwaye kulula ukuyila. Abanzi beemoto basebenzisa iikopi zedip-dip ze-dipgerad eshushu kwimizimba yemoto, izakhelo, kunye namalungu asezantsi. Umaleko we-zinc umisa la malungu avela ekulahleni. Oku kunceda iimoto zihlala zikhuselekile kwaye zisebenza kakuhle. Iinkampani zemoto e-China naseIndiya zisebenzisa i-Galvaniment yentsimbi ye-GAEE ngoku. Bafuna iimoto ezilula nezingcono. Iimoto zombane ngakumbi zithetha ngakumbi iimfuno zolu mbandela. Imithetho emitsha malunga nongcoliseko kunye nokusindisa ipetroli yenza iinkampani zisebenzisa i-Galvanid Couil. Iindlela ezingcono zokuhamba kunye neefektri zendawo zinceda ukuhlangabezana nemfuno enkulu kwezi ndawo.

Olunye usetyenziso

I-Galvanime Couil Clail isetyenziselwa ngaphezulu kwezakhiwo kunye neemoto. Abasebenzi bokwenza isixhobo bayisebenzisa ngeembeyi, iifriji kunye neendawo zomoya. Ayisiyohlwa kwaye ijongeka intle. Esi sixhobo sikwasetyenziswa kumandla aluhlaza kunye neeprojekthi zeSmart. Izithuthi zombane kunye namandla aluhlaza kunye nentsimbi engagungqiyo zezinto ezintsha. E-Asiya-Pacific, ngaphezu kwekota ye-coil yentsimbi esetyenziselwa izixhobo zombane. Iiprojekthi ezintsha zeSixeko kunye neefektri ezizezinye zenza imfuneko yeli ntsimbi inyuka. Iinkampani ngoku zisebenzisa itekhnoloji entsha ukwenza iimveliso zobuchule kunye neemveliso zentsimbi ezizodwa kwezi ntengiso zintsha.

Ukuqwalaselwa kunye nokusikelwa umda

Ukukhetha i-coil elungileyo

Ukukhetha i-coil yentsimbi yomsebenzi kubalulekile. Kuya kufuneka ucinge ngezinto ezininzi. Ezi zinto ziyatshintsha indlela i-coil isebenza ngayo kwaye ihlala ixesha elingakanani.

Ubunzima : Intsimbi emdaka ibambe ubunzima kwaye ihlala ixesha elide. Abakhi basebenzisa i-coms emdaka yezaqabaza kunye neenxalenye zomeleleyo. Iikopi ezicekeceke zilungile kwiinto ezilula njengee-ducts zomoya.

Ukudibana kwesisindo : Ukudibana kwe-zinc kugcina i-rump. Ingubo enzima, njenge-G90, ilungele iindawo ezimanzi okanye ezinetyiwa. Ingubo elula, njenge g60, ilungile ngaphakathi okanye kwiindawo ezinobulali.

Ibanga : Ibakala ngalinye linamandla alo kunye nokubeleka. Amanqanaba aqinileyo alungile xa ufuna intsimbi enzima. Amabanga aguqukayo angcono ukuba ufuna ukugoba okanye ukubumba i-coil.

Ububanzi kunye nobude : ubungakanani bezeziyilingi yesiko ncedo projekthi nganye. Oku kwenza ukuba kube senziwe kwaye kube lula ukuyilwa.

Olunye uqwalaselo : Cinga ngexabiso, uhlobo lomsebenzi, kwaye uza kusebenzisa phi i-coil. I-HOT-dip-dip okanye i-electrogalvaning ikhethwe ngokuxhomekeke kwinto oyifunayo.

Icebiso: Soloko ujonge kwimithetho yemveliso kwaye ujonge umgangatho womthengisi ngaphambi kokuba uthenge.

Izinto zokusingqongileyo

Indawo osetyenziswa kuyo i-sela yensimbi ingayitshintsha indlela abasebenza ngayo. Ityiwa emoyeni kufutshane nolwandle lwehla i-zinc ngokukhawuleza. Ungcoliseko oluvela kwiifektri luyenza imvula ene-acid enxiba i-zinc. Ukugcina iikoreyi kwiindawo ezinamanzi kunokuyibamba amanzi kwaye kubangele ukuba umhlwa omhlophe. Ubushushu obuphezulu buvela kwi-welding okanye ukusika kunokuyitshisa i-zinc kwaye bashiye intsimbi ivulekile ukuba ivulwe.

Okusingqongileyo |

Umngcipheko ophambili |

Inyathelo lokukhusela |

Unxweme |

Ityuwa yokutshiza, imbiza |

Sebenzisa i-zinc enkulu ye-zinc |

Ishishini |

Imvula ye-acid, i-corrosion |

Faka isicelo sokudlulisa, imiphetho yokutya |

Ukugcinwa komswakama |

Ukuqulunqwa okumhlophe |

Gcina kwindawo eyomileyo, enomoya |

Imiba eqhelekileyo

I-SENIL zensimbi zinokuba neengxaki xa zisetyenziswa okanye zigcinwe:

I-run emhlophe inokubonisa ukuba amanzi ahlala kwi-coil, ngakumbi ukuba idreyishini alwenziwa kakuhle.

Ukutyibilika, ukunqunyulwa, okanye i-welding kunokwenzakalisa ungqimba lwe-zinc kwaye wenze ukuqhekeka ngakumbi.

Ukuba i-zinc ayikho nokuba intsimbi inomdaka, amabala abuthathaka anokwenziwa.

Amabala amnyama anokwenzeka ukuba i-run emhlophe iyaqhubeka ikhula.

Ukugcina iikhoyisi eziphosakeleyo, ezinje kwiindawo ezimanzi, zisenze run.

QAPHELA: Ziphathe iikhoyili ngononophelo, uzijonge rhoqo, kwaye uzigcinekele ilungelo lokumisa uninzi lweengxaki.

I-Galvanime Couil Coyiil igcina intsimbi ikhuselekile kwi-rust. Ikwayeka ukonakala. Esi sixhobo somelele kwaye sihlala ixesha elide. Inceda ukusindisa imali. Abakhi bayisebenzisa eluphahleni kunye neendonga. Abavelisi bayisebenzisa ngeemoto kunye nezinto zombane. Abathengi kufuneka bajonge ubukhulu kunye nobunzima obukhulu. Bamele bajonge inqanaba. Imigangatho ye-ASTM inceda uqiniseke ukuba i-coil ilungile. Ukufuma kunye netyuwa emoyeni kunokutshintsha indlela esebenza ngayo. Ukukhetha i-coil elungileyo inika iziphumo ezingcono.

FAQ

Yeyiphi eyona njongo ye-Galvanimed Coyiil?

I-Galvanity Couil Couil igcina intsimbi ukusuka kwi-rusting okanye eyonakalisiweyo. Ubeko lwe-zinc lusebenza njengekhaka. Abakhi kunye neefektri basebenzise ukwenza iinxalenye ezihlala ixesha elide kwaye zihlala zomelele.

I-zinc iqeqesha njani i-rust?

I-Zinc idibana namanzi nomoya ngaphambi kokuba kwenziwe intsimbi. Oku kwenza umaleko okhethekileyo ngaphezulu. Umaleko uyeka amanzi kunye nomoya ekuchukumeni kwentsimbi.

Basebenzisa phi abantu kwi-Galvanid Clail rhoqo?

Abantu basebenzisa i-Galvanid Couil ekwakheni, ukwenza iimoto, kunye nokwenza izixhobo. Kulungile ukuba uphahla, amalungu eemoto, kunye neziqwenga zomatshini.

Ngaba i-gavaninited coyinti ipeyintiwe?

Ungayipeyinta i-Gavanimoted Coil. Umphezulu kufuneka ucoceke kwaye womile kuqala. Iiprimers ezikhethekileyo zinceda intonga yepeyinti kwi-zule ye-zinc.

Yeyiphi imigangatho esebenzayo kwi-Galvanid Couil?

I-A653 kunye ne-ISO 3575 yeyona mithetho iphambili ye-Galvamid Coil. Le mithetho ithetha malunga nokuba ubukhulu bengceni